Automatic Vertical Silicone Sealant Cartridges Filling Machines,

also for Bituminous Products

Fully automatic machines with vertical filling, single, double or triple head, depending on the required production speed.

For filling high and very high viscosity sealants in standard 260 to 310 ml cartridges (silicone, silicone sealants, acrylic sealants, polyurethane sealants).

Totally pneumatic and ATEX filling machines

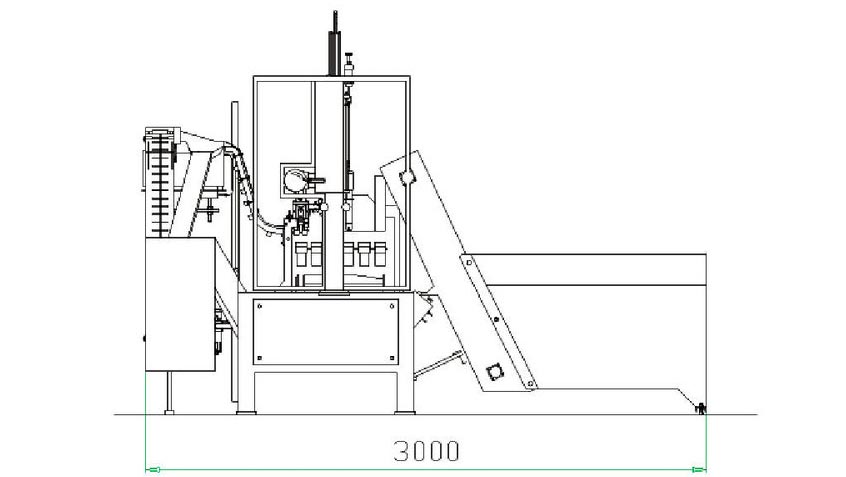

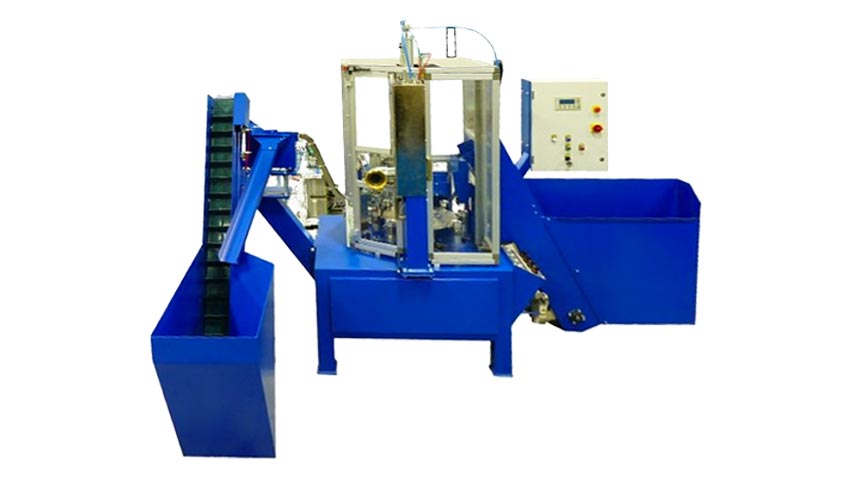

Mod. C25 single head

Mod. C25 is also available in a modified version for working with aluminum cartridges to be closed with an aluminum plunger to be expanded.

Mod. C40 double head

Mod. C50 triple head

- Totally automatic machines with fully pneumatic operation, not requiring any electrical connection, suitable to hazardous areas (also in ATEX-Ex certified version).

- Automatic feeding of cartridges and plungers by means of loading hoppers on the ground for easy loading by the operator.

- Automatic loader of empty cartridges and automatic loader of plungers, with discarder of badly oriented cartridges and plungers.

- Vertical volumetric dosing unit with single, double or triple head (depending on the required production speed) with adjustable volume.

- Parts in contact with the product made of carbon steel or stainless steel.

- 3-way valve of the rotor + stator (cube) type, for practical disassembly and reassembly (separate cartridge conduits in the double and triple versions).

- Vertical filling of the cartridge for maximum flexibility in filling products of any viscosity, from liquid to high viscosity, having millions of cP/mPa.

- Filling of the cartridge from the bottom upwards, with controlled lowering device to avoid the formation of air bubbles during filling.

- Product cut-off valve in rubber with suction rod, or mechanical mushroom cut-off valve with anti-drop profile.

- First pressing unit for the insertion of the plunger inside the cartridge.

- Second pressing unit with shaped pusher to deform the plastic plunger during pressing in order to completely evacuate the air between plunger and product.

- Station for the ejection of the filled and closed cartridge in horizontal position.

- Cartridge and plunger presence controls.

- Production speed up to 25, up to 40 and up to 50 cartridges/minute.

PLC electro-pneumatic Filling Machines

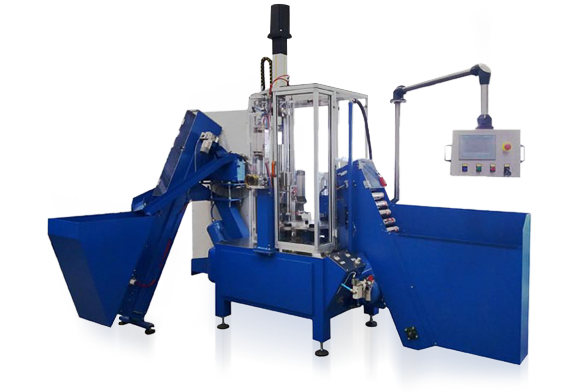

Mod. C35E single head

Mod. C35E is also available in a modified version for working with aluminum cartridges to be closed with an aluminum plunger to be expanded.

Mod. C50E double head

Mod. C60E triple head

Mod. C80E triple head

- Totally automatic machines with electro-pneumatic operation, for maximum production performance and on-board diagnostics.

- PLC and touch screen 7″ display Siemens or, on request, Allen Bradley, Omron, or ASEM with remote control system for assistance from our office.

- Automatic feeding of cartridges and plungers by means of loading hoppers on the ground for easy loading by the operator.

- Automatic loader of empty cartridges and automatic loader of plungers, with discarder of badly oriented cartridges and plungers.

- Vertical volumetric dosing unit with single, double or triple head (depending on the required production speed) with adjustable volume.

- Parts in contact with the product made of carbon steel or stainless steel.

- 3-way valve of the rotor + stator (cube) type, for practical disassembly and reassembly (separate cartridge conduits in the double and triple versions).

- Vertical filling of the cartridge for maximum flexibility in filling products of any viscosity, from liquid to high viscosity, having millions of cP/mPa.

- Filling of the cartridge from the bottom upwards, with controlled lowering device to avoid the formation of air bubbles during filling.

- Product cut-off valve in rubber with suction rod, or mechanical mushroom cut-off valve with anti-drop profile.

- First pressing unit for the insertion of the plunger inside the cartridge.

- Second pressing unit with shaped pusher to deform the plastic plunger during pressing in order to completely evacuate the air between plunger and product.

- Station for the ejection of the filled and closed cartridge in horizontal position.

- Cartridge and plunger presence controls.

- Production speed up to 40, up to 70, up to 84 and up to 100 cartridges/minute.

- Optional: dosing system with electric cylinder, modem for remote control and assistance, nitrogen spray, etc.

Automatic filling machines in aluminum cartridges

with easy-open lid to be crimped

Totally automatic single head machines for the filling of high and very high viscosity sealants in standard 310 ml aluminum cartridges to be capped with a plastic plunger and easy-open lid to be crimped, or optionally also with and aluminum plunger to be expanded.

Mod. C30ES without expanding device for the aluminum plunger

Same features as the C35E, but with the following stations:

- Station for positioning the silica gel (anti-moisture hygroscopic salts) with tank for the bulk gel, or with bowl vibrator feeder for the tableted gel.

- Station for the positioning of the easy-open lid on the cartridge, with vertical reservoir of the stacked caps and suction-cup separator of the lids.

- Station for crimping the lid at the cartridge.

- Production speed up to 20 or 30 cartridges/minute.

- The machine can also work with standard plastic cartridges to be closed with a plastic plunger.

- Optional: dosing system with electric cylinder, modem for remote control and assistance, nitrogen spray, step-by-step eject belt, etc.

Mod. C30EES with aluminum plunger expander

The true all-in-one machine for filling and closing aluminum cartridges.

Both with aluminum plunger to be expanded and with easy-open lid to be crimped.

To be able to choose the desired solution for each lot of cartridges to fill and close.

- Same features as C30ES with station for the silica gel, station for the positioning of the easy-open lid and crimping station, but with the addition of the station for the aluminum plunger expansion.

- The machine that can also work with standard plastic cartridges to be closed with a plastic plunger.

- Optional: dosing system with electric cylinder, modem for remote control and assistance, nitrogen spray, step-by-step eject belt, etc.

Nannini Renato Custom.

Thanks to our entirely in-house Design and Production Departments, we are able to meet any customization request,

taking into full account the timing needs of your business.

Request more information.

Get in touch with us.